paper archives

Stay hungry, stay foolish. You are as good as your last paper.

Dual polymer engineering enables high-performance 3D printed Zn-organic battery cathodes

- Wanli Gao, Christian Iffelsberger, Martin Pumera*

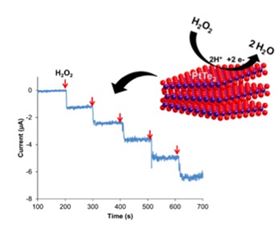

Fused deposition modeling (FDM) 3D-printed one-dimensional (1D) carbon materials show great potential as skeletons for newly emerged aqueous Zn-organic batteries due to their well-entangled conductive networks and design flexibility in on-demand fabrication. However, (i) the insulating character of commonly used thermoplastic polymers in FDM 3D printing and (ii) the incompatibility between organic cathodes and cost-efficient aqueous mild electrolytes present a stumbling block for the current development of FDM 3D-printed Zn-organic batteries. Targeting these two aspects, this work proposes a dual-polymer-engineered cathode for high-performance Zn2+ storage. The engineering consists of (i) a crystallinity engineering of insulating poly(lactic acid) (PLA) in 3D-printed carbon frameworks to confine the nanocarbon accommodation space to form a more compact conductive network, and (ii) a protonation engineering of polyaniline (PANI) by in situ introduction of polyacrylic acid (PAA) during electrodeposition process to construct an internal proton reservoir for reversible redox reactions of PANI. Such dual-polymer-engineered cathode (3D@PANI-PAA) presents a reversible capacity of 214.6 mAh g−1 at 0.4 A g−1, good rate performance (117.2 mAh g−1 at 3.2 A g−1), and much improved cycling stability over 1000 cycles (78.1% capacity retention). This combined approach delivers new concepts to construct reliable aqueous Zn-organic batteries and enlarges the FDM 3D printing for electrochemical energy storage applications.